CSC, Korean Make Soft Magnetic Powder Cores

Global No.1, Soft Magnetic Powder Cores

Alloy Powder Cores are soft ferromagnetic cores made from ferrous alloy powders, after insulating , mixed pressed with in-organic binder then annealing in high temperature. Alloy Powder Core materials are pressed with an in-organic binder, so there is no thermal aging. Alloy Powder Cores are distributed air gap cores that are primarily used in power inductor applications, such as switched-mode power supply (SMPS) output filters, differential inductors, boost inductors, buck inductors, and flyback transformers. Alloy Powder Core materials are high resistivity, low hysteresis and eddy current losses and excellent inductance stability under both DC and AC conditions.

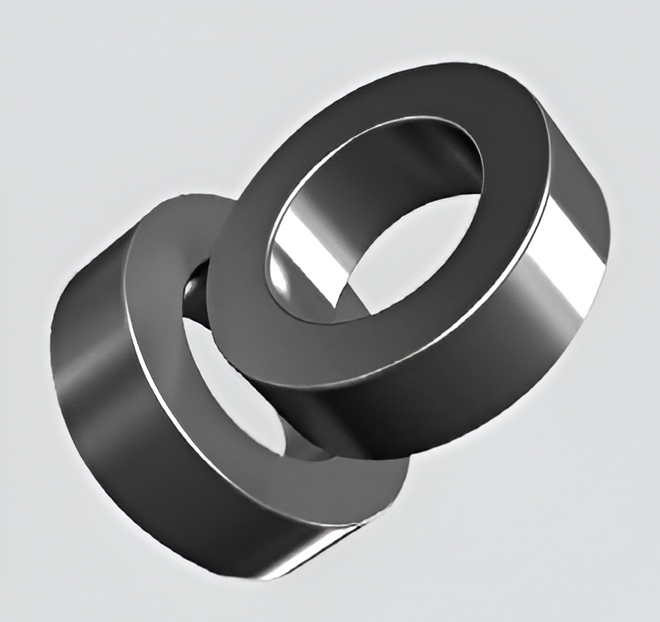

Toroidal Alloy Powder Cores

Alloy Powder Cores are soft ferromagnetic cores made from ferrous alloy powders, after insulating, mixed pressed with in-organic binder then annealing in high temperature. Alloy Powder Core materials are pressed with an in-organic binder, so there is no thermal aging. Alloy Powder Cores are distributed air gap cores that are primarily used in power inductor applications, such as switched-mode power supply (SMPS) output filters, differential inductors, boost inductors, buck inductors, and flyback transformers. Alloy Powder Core materials are high resistivity, low hysteresis and eddy current losses and excellent inductance stability under both DC and AC conditions.

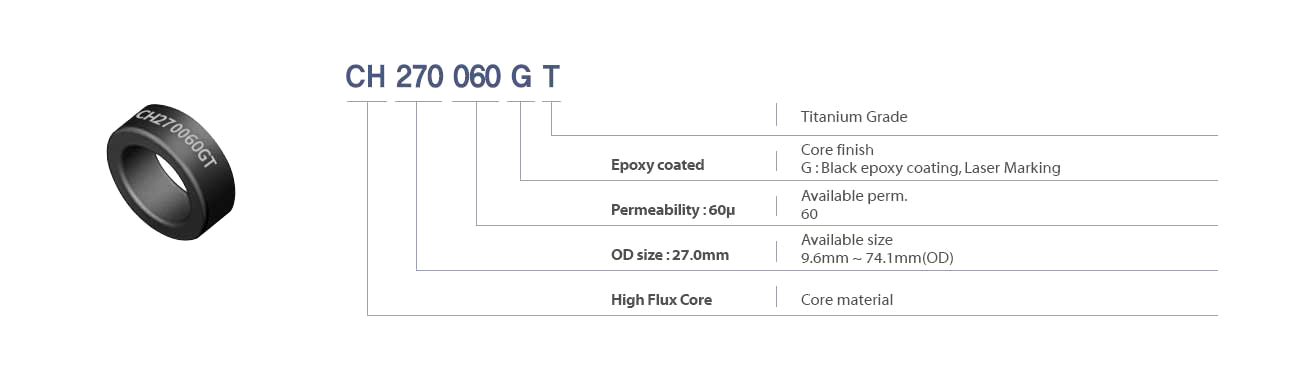

Titanium Grade: High Flux GT Core (CH GT)

High Flux GT is the world's highest performance high flux material created by CSC's innovative manufacturing process, and is specialized for on-board chargers for servers and telecom power supplies and EV vehicles that require high efficiency. CSC's great achievement, High Flux GT, enables users to optimize PFC and output inductor designs by providing higher DC bias and lower core loss of approximately 25% at 200kHz compared to conventional High Flux. Core available with Permeability of 26 µi, 60 µi and 125 µi.

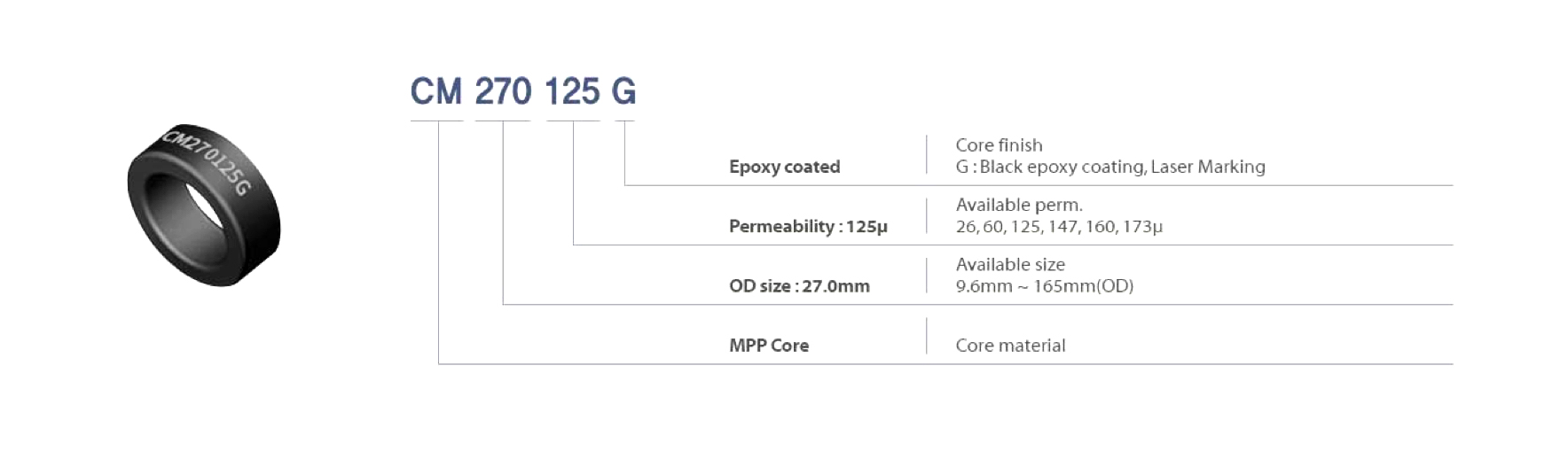

MPP Cores (CM G)

MPP cores are materials that offer low core loss and high permeability, exhibiting very good temperature and inductance stability under high DC magnetization or high DC bias applications. It is mainly used as a premium material for DC output inductors for SMPS, including high Q filters, loading coils, and EMI/RFI filters in aerospace, defence, and medical applications where high reliability and stability are required. Core available with Permeability of 26 µi, 60 µi , 125 µi, 147 µi, 160 µi and 173 µi.

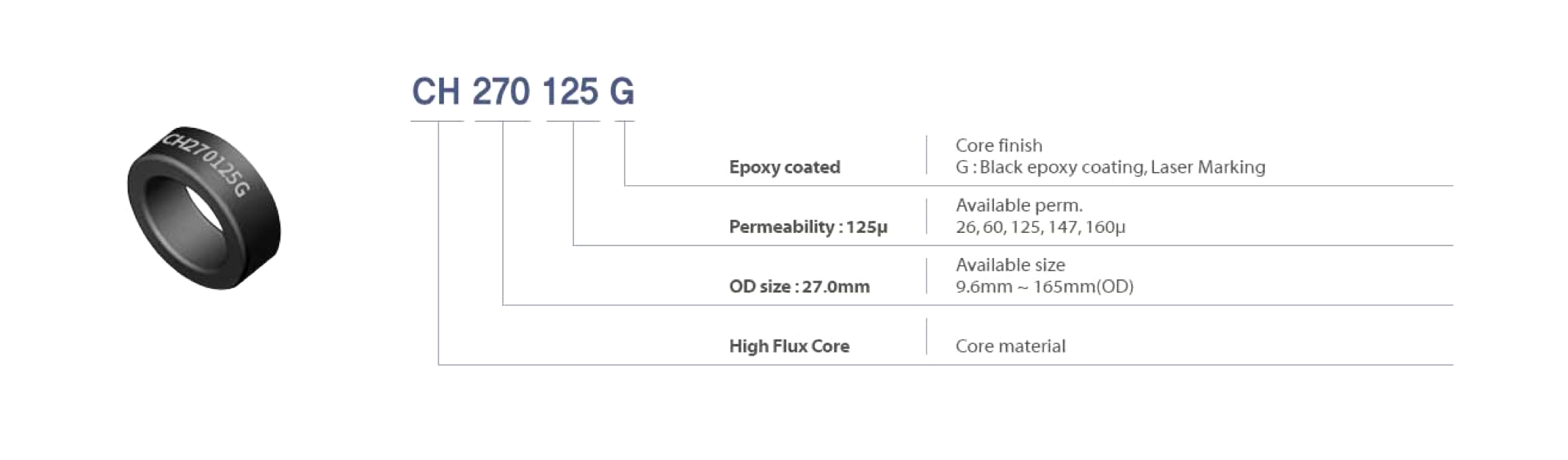

High Flux Cores (CH G)

High Flux cores with 15,000 Gauss saturation levels have higher energy storage capacity and permeability compared to the performance of similarly sized gap ferrite or powdered iron cores. The high flux core's excellent DC Bias properties and low core loss reduce inductor size and windings and provide superior magnetic properties. CSC's High Flux cores are an excellent choice for applications such as PFC inductors, switching regulator inductors, in-line noise filters, pulse transformers, and flyback transformers. Core available with Permeability of 26 µi, 60 µi , 125 µi, 147 µi and 160 µi.

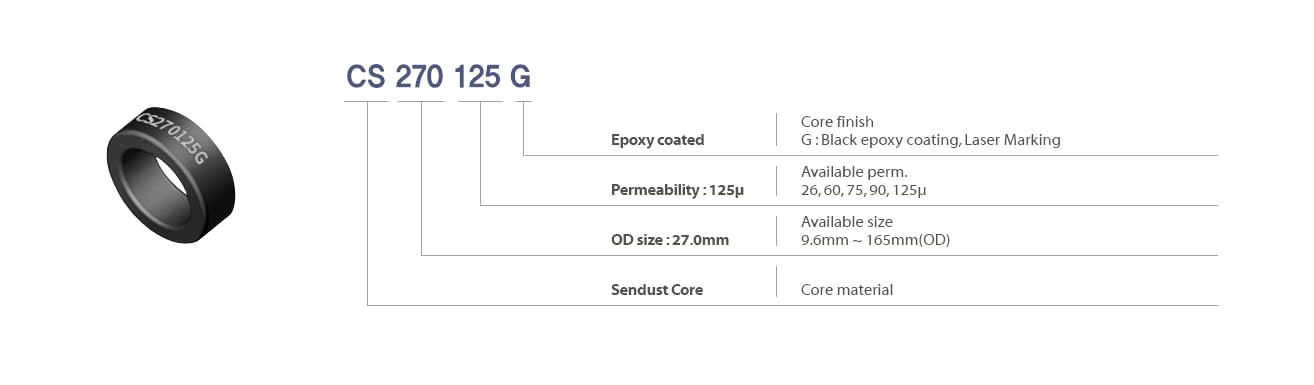

Sendust Core (CS G)

Due to its near-zero magnetostriction, Sendust cores are ideal for eliminating audible noise from filter inductors. The core loss of Sendust cores is much lower than that of powdered iron cores. In particular, the E-shaped Sendust core offers higher energy storage capacity than E-shaped gap ferrite cores. Gap losses and eddy current losses can be minimized by using Sendust E cores. Sendust cores are a smart choice for PFC circuits. Other key applications include switching regulator inductors, in-line noise filters, pulse transformers, and flyback transformers. Core available with Permeability of 26 µi, 60 µi , 75 µi, 90 µi and 125 µi.

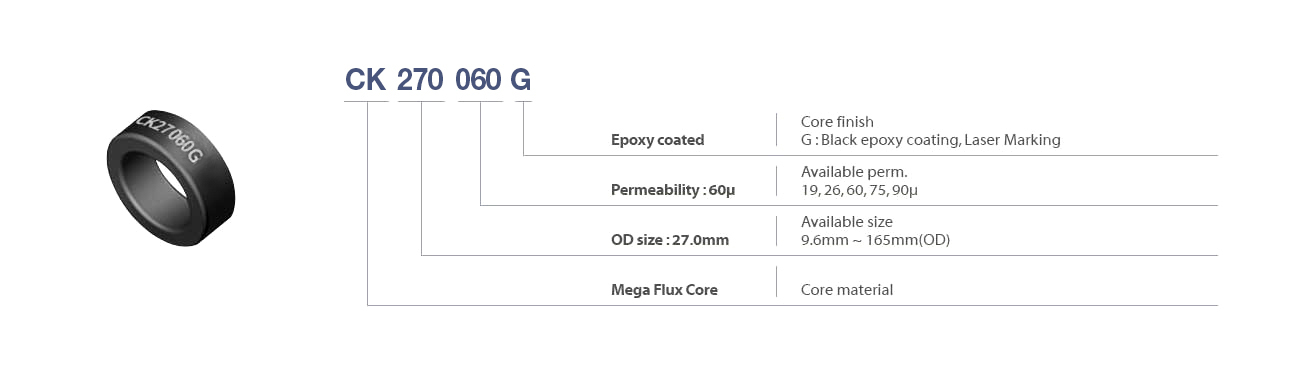

Mega Flux Core (CK G)

CSC is the first company in the world to develop a powdered magnetic core made of iron and silicon. The innovative Mega Flux core has a flux density of 16,000 Gauss, which is higher than other materials such as the 15,000 Gauss High Flux core and the 10,000 Gauss Sendust core. Its excellent DC overlap (DC Bias) provides the best solution for advanced applications, including buck/boost inductors for high-power supply systems, smoothed chokes for inverters, and inductors for electric vehicles. Mega Flux cores have significantly lower core loss than powdered iron cores and Fe-Si strip cores. It also exhibits excellent thermal properties without thermal aging. Core available with Permeability of 19 µi, 26 µi, 60 µi, 75 µi and 90 µi .

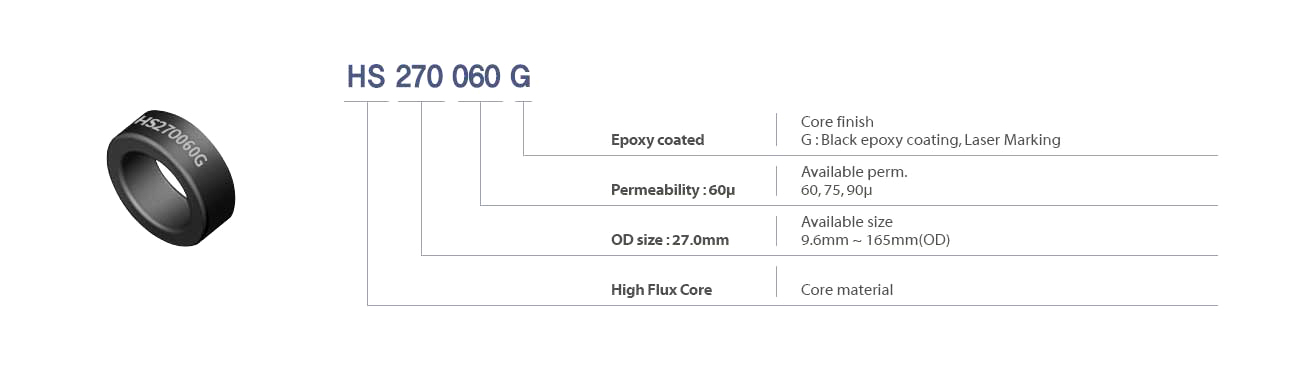

HS Core (HS G)

HS cores have better DCB characteristics and less core loss than Sendust cores. It provides an economical solution for a variety of applications that require high efficiency, such as high-power desktop PCs, server PCs, automotive, and solar power. In addition, it exhibits excellent thermal properties without the thermal aging problems found in other powdered magnetic cores, making it a good alternative to amorphous cores. Core available with Permeability of 60 µi, 75 µi, and 90 µi .

HP Cores (HP G)

HP cores with near-zero magnetostriction are ideal for eliminating audible noise from inductors. In particular, the core loss of HP 19u and 26u is much lower than other materials and even lower than MPP. The HP 19u and 26u provide the right solution for applications that require high efficiency, such as UPS and ESS. The HP 60u is the lowest lossiest material to minimize the temperature rise of the device at high switching frequencies. It is suitable for PFCs and output inductors in small to medium sized power server and EV charger applications. It can be a good alternative to amorphous cores. Core available with Permeability of 19 µi, 26 µi, and 60 µi .

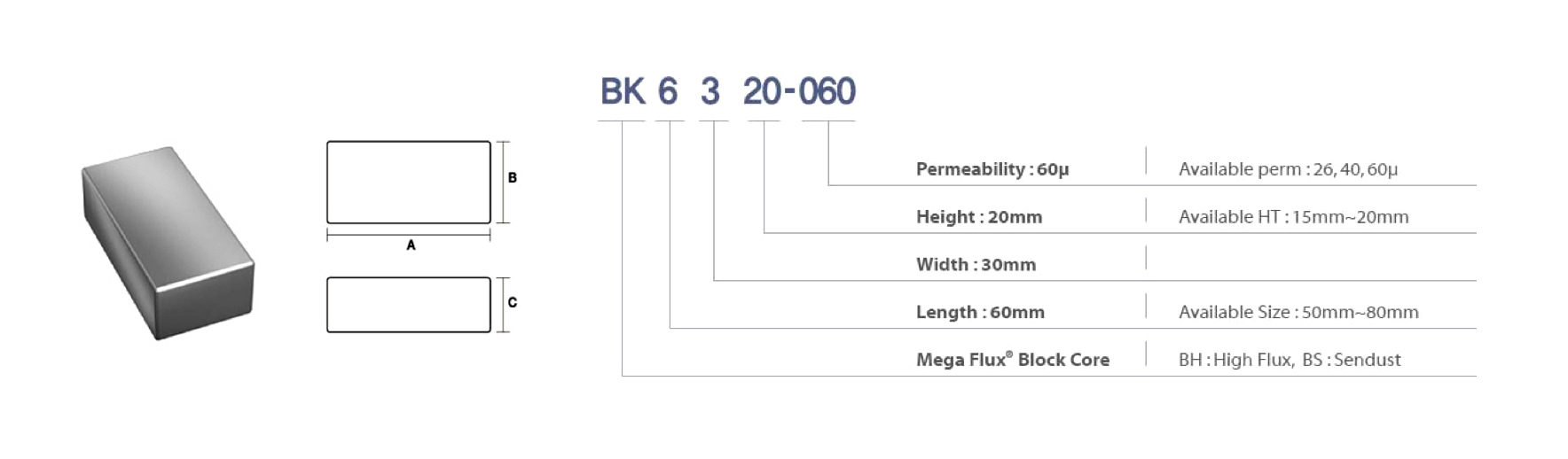

Block Core (BK)

It is possible to realize the structure of various inductors according to the user's convenience, and it is easy to implement a prefabricated inductor with a degree of freedom of a difficult winding shape. In addition, the basic advantages of powdered magnetic cores such as high energy storage capacity, high temperature stability, low core loss, and high operating frequency can be maintained. Core available with Permeability of 26 µi, 40 µi, and 60 µi .

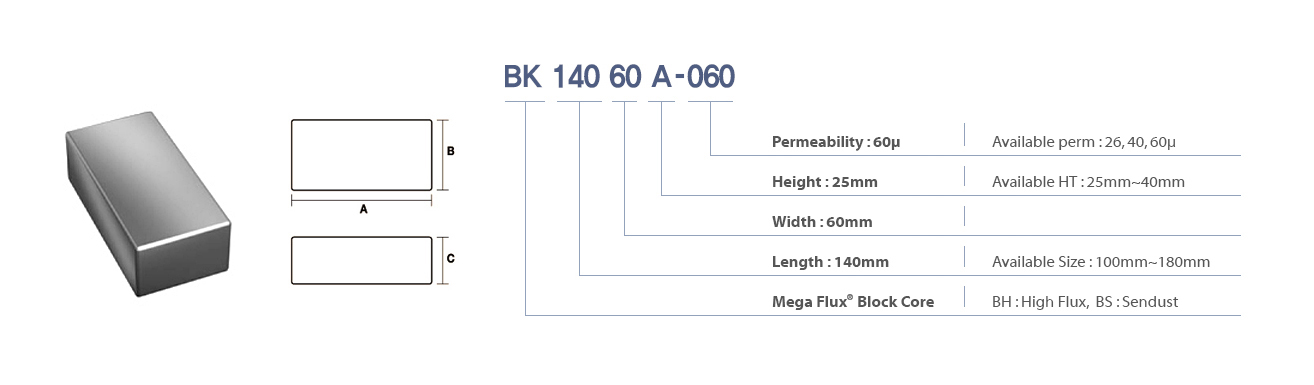

BIG Block Core (BK)

It is possible to assemble a larger inductor core with a larger capacity and realize the structure of various inductors tailored to the user's convenience, and it is easy to implement a prefabricated inductor with a degree of freedom of difficult winding shape. In addition, the basic advantages of powdered magnetic cores such as high energy storage capacity, high temperature stability, low core loss, and high operating frequency can be secured. Core available with Permeability of 26 µi, 40 µi, and 60 µi .

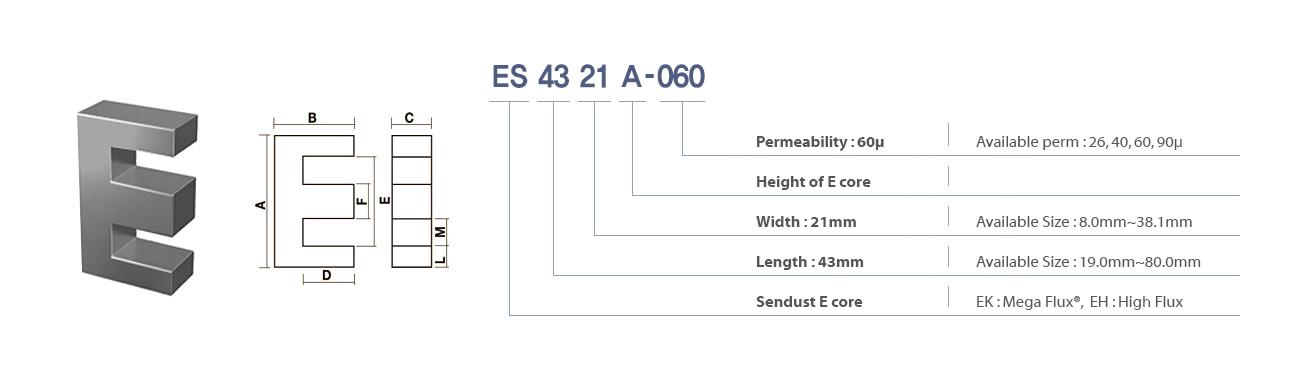

E Core (ES)

It is easy to secure high inductance, and it is easy to implement a lower height inductor than other shapes with the same characteristics. In addition, the basic advantages of powdered magnetic cores such as high energy storage capacity, high temperature stability, low core loss, and high operating frequency can be secured. Core available with Permeability of 26 µi, 40 µi, 60 µi and 90 µi .

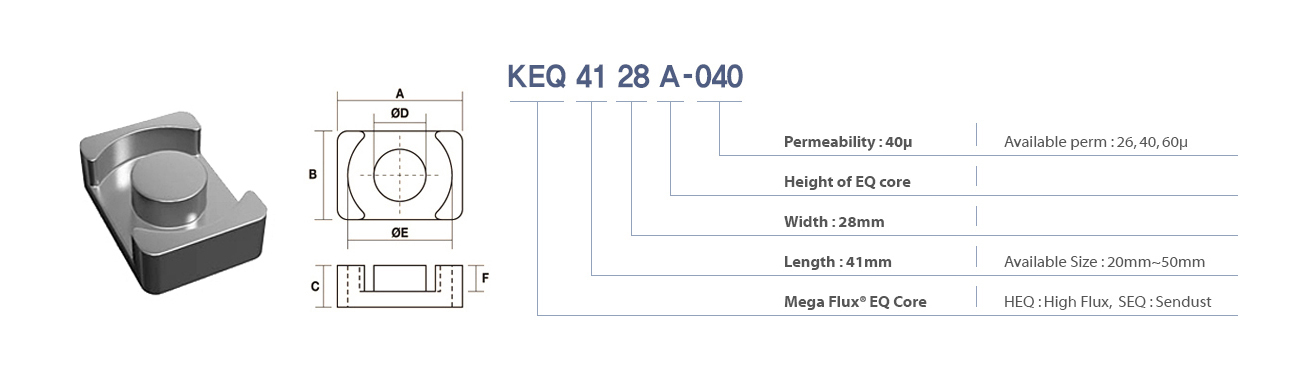

EQ Core (KEQ)

It is suitable for realizing inductance with a high current capacity, and it is easy to make an inductor with a lower height than any other shape of core. In addition, the basic advantages of powdered magnetic cores, such as high energy storage capacity, high temperature stability, low core loss, and high operating frequency, can be secured and maintained, and it is possible to select and utilize cores with standardized permeability without additional processes such as gap processing. Core available with Permeability of 26 µi, 40 µi, and 60 µi .

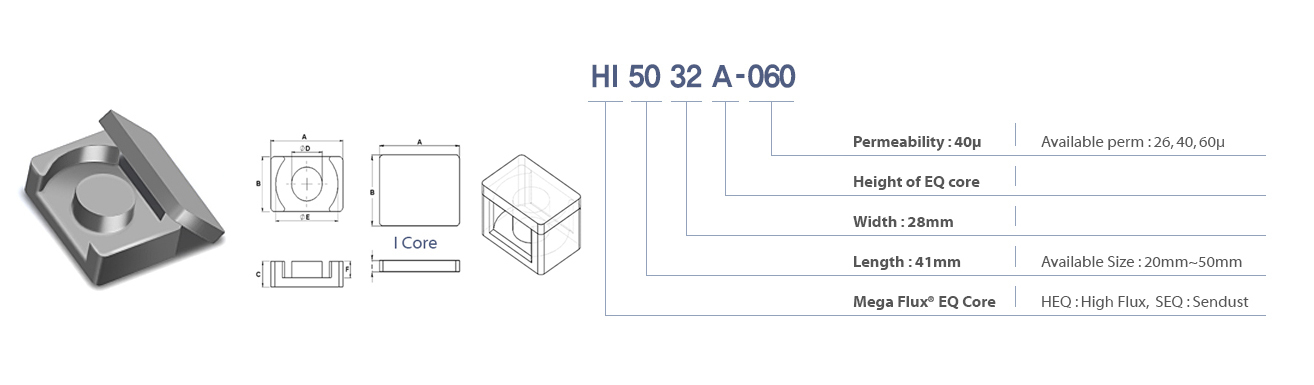

EQ + I Core (HI)

It is suitable for securing inductance with a high current capacity, and it is easy to implement an inductor with a lower height than any other shape of core. In addition, the basic advantages of powder magnetic core, such as high energy storage ability, high temperature stability, low core loss, and high operating frequency, can be secured and maintained, and it is possible to select and utilize a core with standardized permeability without additional processes such as gap processing. Core available with Permeability of 26 µi, 40 µi, and 60 µi .

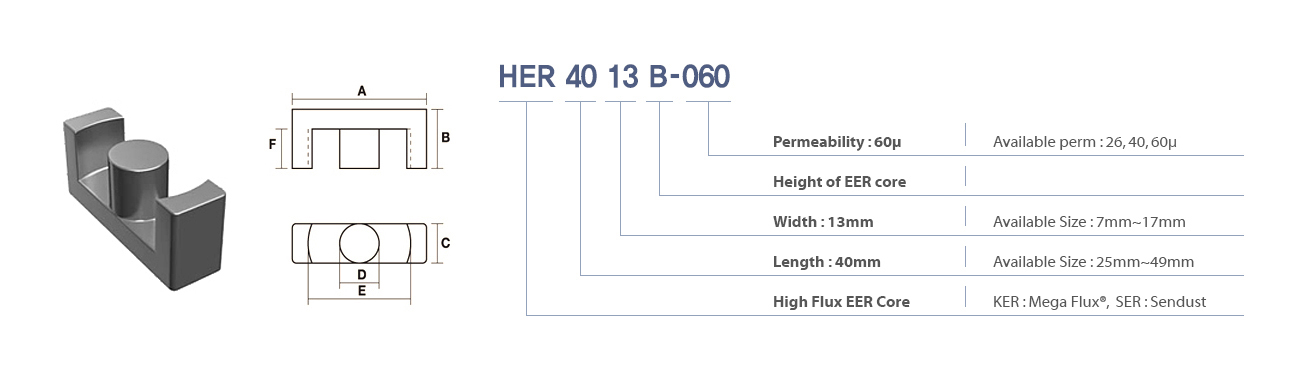

EER Core (HER)

It is suitable for realizing inductance with a large current capacity, and it is the optimal core shape that makes it easy to prepare for winding in advance. In addition, the basic advantages of powdered magnetic cores, such as high energy storage capacity, high temperature stability, low core loss, and high operating frequency, can be secured and maintained, and it is possible to select and utilize cores with standardized permeability without additional processes such as gap processing. Core available with Permeability of 26 µi, 40 µi, and 60 µi .

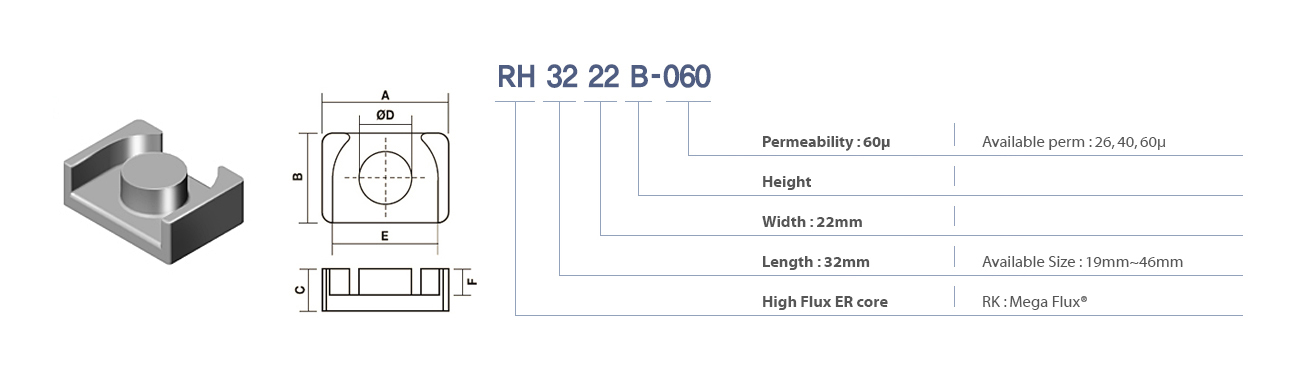

ER Core (RH)

It is a good core shape for realizing a high current capacity and a low-height inductor, and it is easy to select the inlet and withdrawal location of the winding, making it convenient to configure the circuit and mount the inductor. In addition, the basic advantages of powdered magnetic cores, such as high energy storage capacity, high temperature stability, low core loss, and high operating frequency, can be secured and maintained, and it is possible to select and utilize cores with standardized permeability without additional processes such as gap processing. Core available with Permeability of 26 µi, 40 µi, and 60 µi .

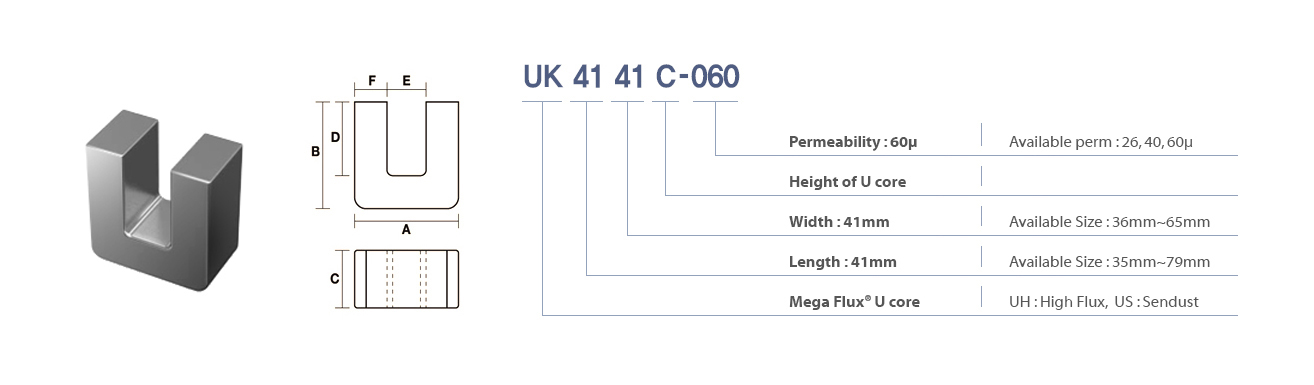

U Core (UK)

It is suitable for inductors with high current capacity and high inductance, and it is easy to assemble through pre-winding and can minimize the area in the circuit. In addition, the basic advantages of powdered magnetic cores, such as high energy storage capacity, high temperature stability, low core loss, and high operating frequency, can be secured and maintained, and it is possible to select and utilize cores with standardized permeability without additional processes such as gap processing. Core available with Permeability of 26 µi, 40 µi, and 60 µi .

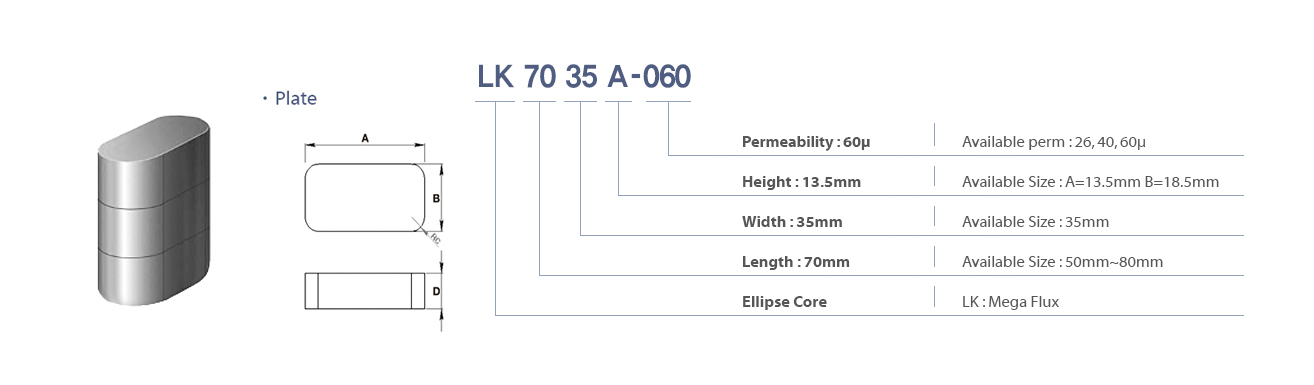

Ellipse Core (LK)

Through easy mixing assembly with block core, etc., inductors of various sizes and characteristics can be freely designed. In particular, when using a core furnace in the winding part, it is possible to realize a large inductor with high efficiency by minimizing the use of winding, insulation breakdown of the bending part, and direct current resistance of the winding part by optimizing the shape. In addition, the basic advantages of powdered magnetic cores such as high energy storage capacity, high temperature stability, low core loss, and high operating frequency can be secured. Core available with Permeability of 26 µi, 40 µi, and 60 µi .

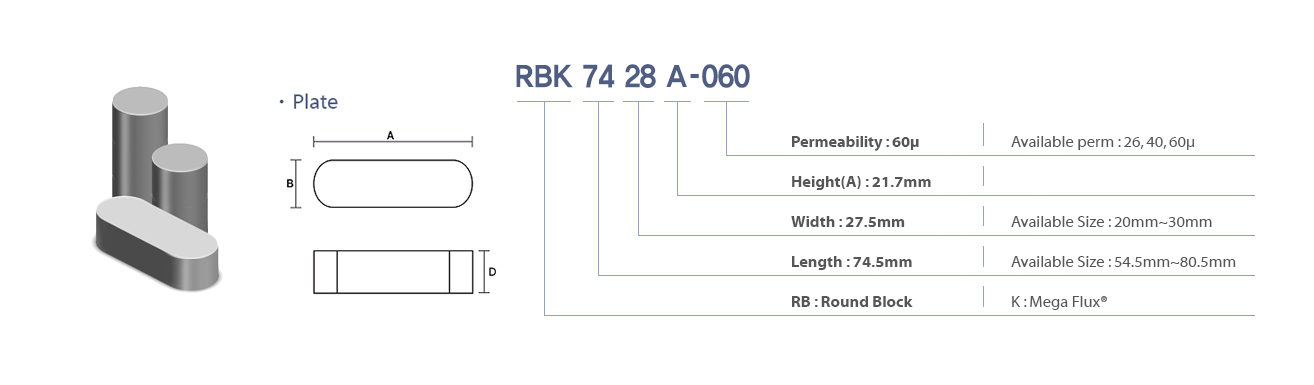

Round Block + Cylinder Cores (RBK)

Through easy mixing assembly with block core, etc., inductors of various sizes and characteristics can be designed independently. In particular, the round shape optimizes the magnetization characteristics of the assembly, and minimizes the amount of winding, insulation breakdown of the bending part, and direct current resistance of the winding part, so that a large inductor with high efficiency can be made. In addition, the basic advantages of powdered magnetic cores such as high energy storage capacity, high temperature stability, low core loss, and high operating frequency can be secured. Core available with Permeability of 26 µi, 40 µi, and 60 µi .

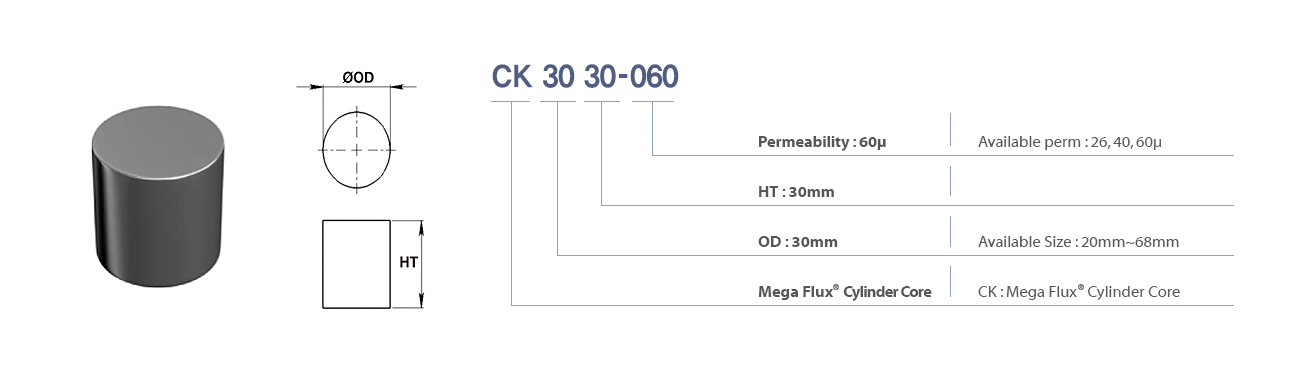

Cylinder Cores (CK)

It can be mixed with blockcore, etc., and through easy assembly configuration, inductors with various sizes and characteristics can be freely designed. It is a core that can realize a large inductor with high efficiency by minimizing the amount of winding, insulation destruction of the bending part, and direct current resistance of the winding part because it is easy to assemble with the winding part. In addition, the basic advantages of powdered magnetic cores such as high energy storage capacity, high temperature stability, low core loss, and high operating frequency can be secured. Core available with Permeability of 26 µi, 40 µi, and 60 µi .

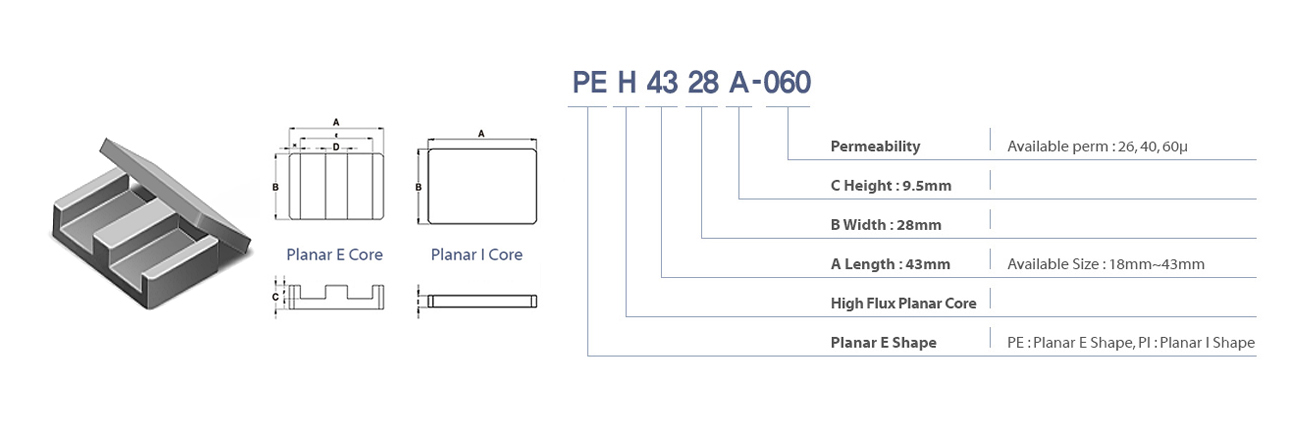

Planar E + I Core (PE H)

The hollow shape, which offers the structural advantage of being thin, provides an optimal solution for small inductors for high currents. It has almost no magnetic field leakage, excellent DC bias characteristics, high temperature stability, and high energy storage capacity. Core available with Permeability of 26 µi, 40 µi, and 60 µi .

HS Core:

HS Toroidal Core: (HS)

Main Features

Applications

HS cores have good DCB characteristics and lower core losses than Sendust cores. They provide an economic solution for applications requiring high efficiency including high power desktop PCs, Server PCs, automotive parts, and solar power parts. They can be a good alternative to Amorphous cores, and also present excellent thermal properties without any thermal aging effects found in other soft magnetic powder cores. This core is available size from ( OD ) 9.65mm to 77.8mm with Permeability of 60 µi, 75 µi, and 90 µi .

KS Core:

KS Toroidal Core: (KS)

Features

Applications

The range of permeability for KS cores is relatively low, 26u~60u, but the 14,000 gauss saturation level allows them to exhibit similar DCB characteristics to High Flux cores. KS cores can be widely used for solar inverters, because they are economic and have a great level of efficiency. They have especially come into the spotlight for large capacity solar inverters. Recently, KS cores have been used in the automobile electricity fields. This core is available size from ( OD ) 9.65mm to 77.8mm with Permeability of 26 µi, 40 µi, and 60 µi .

KH Core:

KH Toroidal Core: (KH)

Features

Applications

The range of permeability for KH cores is 26u~90u. The 15,000 gauss saturation level of KH cores exhibits similar DCB characteristics to High Flux cores, which exhibit the best DCB characteristics among existing materials including Sendust, MPP, and Mega Flux cores. They also have lower losses than Fe-Si based permalloy cores as well as greater frequency characteristics that allow them to be used at a higher frequency. Since KH cores have greater DCB characteristics and a low level of loss, they are most suitable for UPS and ESS applications and other industrial uses. This core is available size from ( OD ) 9.65mm to 77.8mm with Permeability of 26 µi, 40 µi, 60 µi and 90 µi .

HP Core:

HP Toroidal Core: (HP)

Features

Applications

Near-zero magnetostriction makes HP Cores ideal for eliminating audible noise in inductors. Especially, the core losses of HP 19u and 26u are significantly lower than any other material, even lower than MPP. HP cores with 19u and 26u offer good solutions for applications requiring high efficiency such as UPS, ESS and similar industrial uses. HP Cores will be an effective solution for the application which require high efficiency such as Server PC of Titanium level. They can be a good alternative to Amorphous cores, and also present excellent thermal properties without any thermal aging effects found in other soft magnetic powder cores. This core is available size from ( OD ) 9.65mm to 77.8mm with Permeability of 19 µi, 26 µi and 60 µi .

Fine Flux Core:

Fine Flux Toroidal Core: (CF)

Features

Applications

CSC releases new Fine Flux (CF series) powder core which have higher DCB characteristics and similar core losses compare to SENDUST cores. High permeability Fine Flux core 40μ, 60μ will be economic solution for the application which require high efficiency such as high power desktop PC, Server PC, Automotive, Solar power. Find Flux cores with low permeability below 26μ are applied to various large current application where lower losses and excellent DC bias characteristics are critical. They are applied to various applications such as UPS, ESS and other industrial area. This core is available size from ( OD ) 9.65mm to 77.8mm with Permeability of 26 µi, 40 µi and 60 µi .